The Problem and Objective

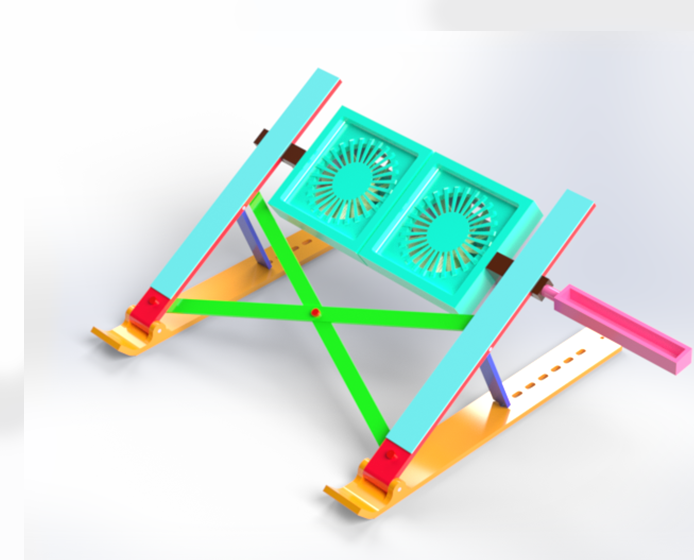

The market for laptop stands and cooling pads suffered from a trade-off between ergonomics, functionality, and portability, often resulting in fixed-fan cooling solutions, complex assemblies, and poor user-friendliness. The initial design of our proposed stand comprised 35 total parts (21 unique components), presenting a clear need for Design for Manufacturability and Assembly (DFMA) optimization.

The core objective was to create an ergonomic, efficient, and modular product by addressing these shortcomings. Specifically, we aimed to:

• Reduce Part Count: Decrease the total number of parts by 10−15% to simplify logistics and assembly.

• Streamline Assembly: Reduce the assembly time by 20% through component consolidation and redesign.

• Optimize Cost: Achieve a 10−15% reduction in overall material and production costs while maintaining high durability and performance.

Technical Solution and Methodology

Our solution involved a systematic DFMA-driven redesign of a novel laptop stand featuring a detachable, modular cooling pad.

Methodology:

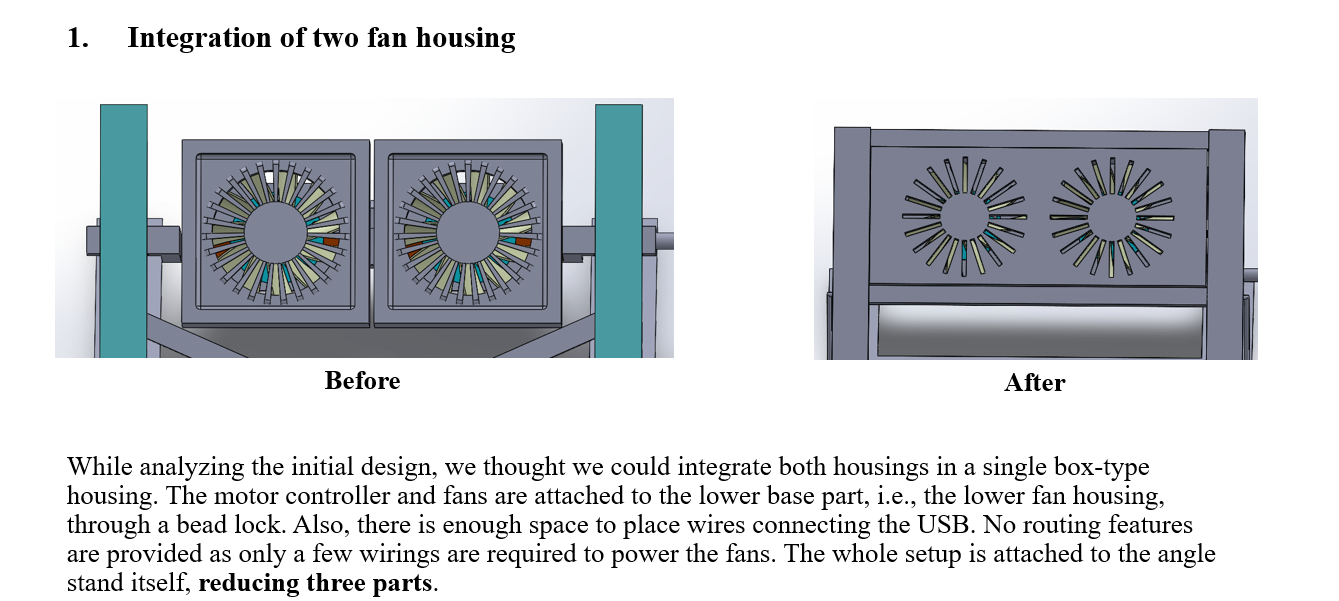

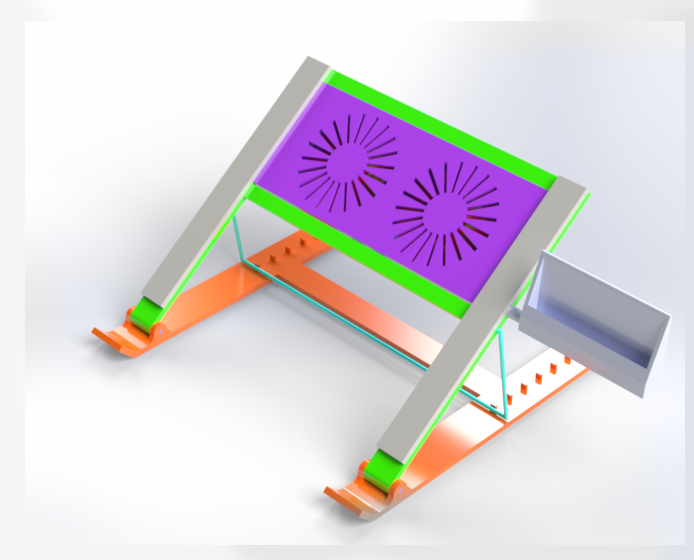

Design for Assembly (DFA): We performed an initial DFA analysis which scored 48.43. Through iterative redesign, we focused on component consolidation, transforming the stand's frame into two primary components and integrating the dual-fan housing into a single box structure. This targeted simplification successfully reduced the total parts from 35 to 22 and interfaces from 67 to 30.

Material Selection and Process Optimization: A detailed analysis using Ashby Charts confirmed the use of ABS Plastic (for fan housing, optimized for Injection Molding), Aluminum 6061 (for structural stands, optimized for Die Casting), and Stainless Steel (for hinge rods, utilizing Machining). This balance ensured a high strength-to-weight ratio, durability, and cost-effective high-volume production.

Usability Improvements: The design integrated the USB hub directly into the cooling pad housing for better cable management and accessibility. The crossbar support was eliminated to fix the optimal width, maximizing cooling efficiency and reducing component count.

Results and Impact

The project culminated in a finalized design that significantly exceeded the original optimization objectives, proving the value of applying rigorous DFMA principles.

Assembly and Manufacturability: The final DFA score was reduced to 25.69 (a reduction of nearly 23 points), validating the substantial simplification of the product architecture. Theoretical and Practical efficiencies improved dramatically to 59.1% (from 45.7% and 40%, respectively).

Economic Impact: The new economic analysis confirmed a reduction in the overall product variable cost (down from $3.91 to $3.81 per unit). The calculated product break-even point for the overall assembly, despite initial fixed costs, was 24,043 units at a sales price of $35, demonstrating clear financial viability for large-scale production.

Product Excellence: The resulting product is more ergonomic, easier to assemble, and maintains high structural integrity while fulfilling the core promise of providing a flexible, high-performance, and cost-optimized cooling and elevation solution.

Design Changes

Auto

1 / 5

Interactive Model

Interactive Assembly

eDrawings ViewerExploded assembly view showing component relationships

Key Results

0

Part Count Reduction

reduced from 35 to 22 parts through DFA optimization and design consolidation

0

DFA Score Reduction

improved from 48.43 to 25.69 using systematic DFA methodology

0

Assembly Efficiency

increased from 40-59% through streamlined design and part consolidation

0

Interface Reduction

reduced from 67 to 30 interfaces through component consolidation

0

Target Achievement

achieved 37% part reduction vs 10-15% target, 20% assembly time reduction goal met

0

Break-Even Point

units at $35 sales price demonstrating financial viability

Before & After

Before

After

Drag the slider to compare before and after results

Technologies & Tools

SolidWorks

Design for Assembly (DFA)

Design for Manufacturability (DFM)

Ashby Charts

Decision Matrices

Material Selection

Economic & Break-Even Analysis

Project Timeline

1

3 weeks

Initial Design & Benchmarking

Researching existing products and developing the initial CAD concept

Deliverables:

- Complete initial CAD model

- Black Box and Glass Box diagrams

- Preliminary Bill of Materials

2

2 weeks

DFA, Material & Economic Analysis

Conducted detailed DFA, material selection, manufacturing process, and economic analyses to identify key optimization opportunities

Deliverables:

- Initial DFA analysis report

- Material selection matrices

- Complete economic and break-even analysis

3

3 weeks

Redesign & Finalization

Based on the analysis, design changes were implemented, and the final CAD model was created

Deliverables:

- Finalized CAD model with integrated components

- New DFA analysis showing 46.9% score improvement

- Final economic and break-even report

Technical Specifications

Final Part Count22 parts

Primary MaterialABS Plastic

Secondary MaterialAluminum

Tertiary MaterialEVA Foam

Manufacturing ProcessInjection Molding and Die Casting

Final DFA Score25.69

Assembly Efficiency59.1%

Break-Even Point24,043 units at $35

Initial Part Count35 parts

Initial DFA Score48.43

InterfacesReduced from 67 to 30

Key Features

Streamlined design through DFA principles, reducing assembly complexity

Optimized material selection for a balance of cost, performance, and weight

Manufacturing process alignment for high-volume scalability and precision

Part consolidation of the frame and cooling pad for improved manufacturability

High-volume production capability ensured through processes like injection molding and die casting

Enhanced user experience with an integrated USB hub and redesigned mobile holder

46.9% improvement in DFA score from 48.43 to 25.69

37% reduction in part count from 35 to 22 components

Team

Interested in Similar Work?

Let's discuss how we can bring innovative engineering solutions to your next project.